Courses by Software

Courses by Semester

Courses by Domain

Tool-focused Courses

Machine learning

POPULAR COURSES

Success Stories

Final Project: Electric Rickshaw modelling

Pratik Mankar AIM Design of an Electric Rickshaw using MATLAB Simulink (three wheel passenger vehicle). ABSTRACT In this project, we work to create the MATLAB model of the ELECTRIC RICKHAEW by doing a PM brushed type DC motor and a suitable Lithium-Ion battery for the motor. Before this, we will remember…

Pratik Mankar

updated on 16 Jan 2023

Pratik Mankar

AIM

Design of an Electric Rickshaw using MATLAB Simulink (three wheel passenger vehicle).

ABSTRACT

In this project, we work to create the MATLAB model of the ELECTRIC RICKHAEW by doing a PM brushed type DC motor and a suitable Lithium-Ion battery for the motor. Before this, we will remember what is Electric RICKHAEW, how it's functioning, and the privileges of EV RICKHAE Then we make an actual EV RICKHAEW model in SIMULINK with suitable blocks from the powertrain block set. My main motto is to examine "how my RICKHAEW performs for any three standard driving cycles showing energy consumption, the temperature rise of motor and controller for vehicle cover around 100 km at constant speed driving 45 kmph. Made a comparison with Mahindra e-Rickhaew and my Simulink model.

OBJECTIVES

Create a detailed MATLAB model of an electric rickshaw (three wheel passenger vehicle).

Rear wheels driven by PM brushed type motor.

Assume efficiency points of motor controller and motor.

Make an excel sheet of all input and assumed data.

Results: For any three standard driving cycles show energy consumption, temperature rise of motor and controller for 100 km constant speed driving at 45 kmph.

Block Diagram

In the designed Electric Rickshaw main blocks are Battery, drive cycle, controller, DC Motor, Vehicle body & Transmission system. Drive cycle is the input data like how a human drive his actual vehicle here FTP75, WOT & Federal Test Procedure Motorcycle drive cycles are used to make the designed vehicle to give the output how it reacts to the drive cycle. The main objective is to obtain the speed by the driver, to estimate the temperature of Motor and Controller, to estimate the sates of charge (SOC), distance travelled by the vehicle. There is a SOC block that will estimate the state of charge of a battery, distance is calculated by speed and time parameters for all the three Drive cycles.

The body design is varied from load carriers, passenger vehicles with no roof, to full body with windshield for drivers comfort. It consists of a controller unit. They are sold on the basis of voltage supplied and current output, also the number of MOSFET (metal oxide field-effect transistors) used. The battery used is mostly a lead-acid battery with a life of 6-12 months. Deep cycle batteries designed for electric vehicles are rarely used. The weight of the electric car has also been a recurring design difficulty in them.

MATLAB Model of an Electric Rickshaw

Initially the current flows to DC Motor from the battery through the DC-DC power converter to drive the motor. The required voltage will be controlled in the controller. The Controller will follow the given drive cycle reference and run the motor in the required rpm. Then the motor power is transmitted to the wheels of a vehicle through the gear box. and the controller will take the vehicle speed and compare and controlled.

Model parameters

Drive Cycle

Drive cycle is assumed as the driver's input of a vehicle, it replaced how a driver will drive a vehicle. Here I have used three drive cycles which is used to test the vehicle performances. These drive cycle will have high speed, low speed, braking conditions in it. There are different drive cycles like WOT, FTP75 etc., Here in this model I have used FTP 75, WOT & Federal Test Procedure Motorcycle drive cycles.

FTP75

Federal Test Procedure Motorcycle

While Class II and III Highway Motorcycles (at or above 170 cc) still follow the standard FTP, Class I-B Motorcycles (50 to < 170 cc) follow this reduced-speed Motorcycle FTP. It is equivalent to the standard FTP except from 164 to 332 seconds, and again from 1533 to 1701 seconds. It is represented here in kilometers per hour (kph).

Wide Open Throttle (WOT)

All 3 Drive cycles are controlled by the controller provided above by constant through Multi-port switch.

Driver Controller.

A parametric longitudinal speed tracking controller for generating normalized acceleration and braking commands based on reference and feedback velocities.

Use the external actions to input signals that can disable, hold, or override the closed-loop commands determined by the block. The block uses this priority for the input commands: disable, hold, override.

Drive cycle is connected to a longitudinal driver, it has six ports namely velocity reference, velocity feedback, grade, info, Acceleration, Deceleration.

VelRef is given by the drive cycle data and VelFdbk is given by the output of the motor. These two will get compare and the acceleration or deceleration output will be given to the motor controller. Accelcmd is given the PWM generator block and deccelcmd is given to the regenerative port of the h-bridge which uses to generate regenerative braking. Info is used to get any other data from a longitudinal driver block. The grade is to give the input of gradeability to the driver block. This block helps to generate regerate the driver's conditions of the vehicle using the driver cycle block.

- I used default parameters and control type PI

Motor Controller

Controlled PWM Voltage source

This block creates a Pulse-Width Modulated (PWM) voltage across the PWM and REF ports. The output voltage is zero when the pulse is low, and is equal to the Output voltage amplitude parameter when high. Duty cycle is set by the input value. Right-click the block and select Simscape->Block choices to switch between electrical +ref/-ref ports and PS input u to specify the input value.

At time zero, the pulse is initialized as high unless the duty cycle is set to zero or the Pulse delay time is greater than zero.

The Simulation mode can be set to PWM or Averaged. In PWM mode, the output is a PWM signal. In Averaged mode, the output is constant with value equal to the averaged PWM signal.

Select Simulation mode as Averaged.

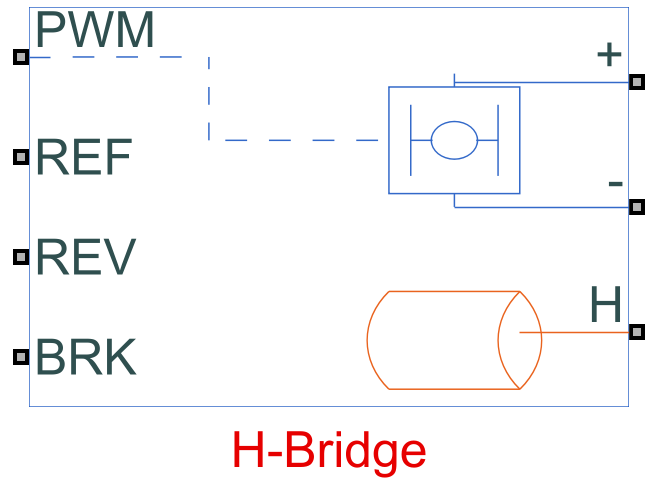

H-Bridge

H-Bridge is used as a DC-DC converter

This block represents an H-bridge motor drive. The block can be driven by the Controlled PWM Voltage block in PWM or Averaged mode. In PWM mode, the motor is powered if the PWM port voltage is above the Enable threshold voltage. In Averaged mode, the PWM port voltage divided by the PWM signal amplitude parameter defines the ratio of the on-time to the PWM period. Using this ratio and assumptions about the load, the block applies an average voltage to the load that achieves the correct average load current. The Simulation mode parameter value must be the same for the Controlled PWM Voltage and H-Bridge blocks.

If the REV port voltage is greater than the Reverse threshold voltage, then the output voltage polarity is reversed. If the BRK port voltage is greater than the Braking threshold voltage, then the output terminals are short circuited via one bridge arm in series with the parallel combination of a second bridge arm and a freewheeling diode. Voltages at ports PWM, REV and BRK are defined relative to the REF port.

If exposing the power supply connections, the block only supports PWM mode.

MOTOR

DC Motor

This block represents the electrical and torque characteristics of a DC motor includes Thermal port to series the temperature of Motor. The block assumes that no electromagnetic energy is lost, and hence the back emf and torque constants have the same numerical value when in Si units Motor. Motor parameters can either be specified directly or derived from the no-load speed and stall torque. If no information is available on armature inductance, this parameter can be set to some small non-zero value. When a positive current flows from the electrical to-ports, a positive torque acts from the mechanical C to R ports. Motor torque direction can be changed by altering the sign of the back-emf or torque constants.

The Motor controller will get input from the longitudinal driver. Its tasks are to control the speed of the motor and drive according to the input of the driver. Majorly motor controlled we designed had two main parts named PWM voltage generator and H-Bridge Input 1 is getting from the accelmd of a longitudinal driver and it is given to a controlled voltage source block where it is input to the controlled PWM voltage will generate a PWM signal in such a way that H-bridge will generate the required voltage to operate the DC motor for the given driver input. PWM voltage block negative reference and REF are grounded and REF of H bridge respectively. H-bridge is a motor controller that has IGBT components aligned in the shape of H and will operate only two at a time respectively to the input of the signal from the PWM block.

When deceleration occurs this H-bridge will give an output from the positive and negative terminals of it. These negative & positive terminals are later connected to the DC motor and battery. All these components are the simscape electrical components so they need a connection to the solver configuration block which helps to solve the simulation.

Temperature Sensor

Temperature Sensor is used to mesure the temperature of H-Bridge and Motor.

This block measures temperature in a thermal network. There is no heat flow through the sensor. The physical signal port T reports the temperature difference across the sensor. The measurement is positive when the temperature at port A is greater than the temperature at port B.

References

Electrical Reference

Used to ground the all the electrical connections.

Mechanical Rotational Reference

Used to ground all the mechanical rotational parts.

Thermal Reference

Used to ground the thermal sensor.

Vehicle Body & Transmission

Motor will produce the rotational output which will give to the vehicle body and transmission system. The rotational output is taken by the gear system here to maintain the constant speed throughout the transmission without any loss in speed from the motor to tires. Below is a diagram that is how it is how it inside the vehicle body and transmission system and in the main design, it is referred just only as a transmission system.

The gear output is given to axels of Rear tires, in the circuit it is shown that gear is connected to Rear wheels and front tire is free to rotational motion, thus vehicle moves forward. N is the normal force caused by the tires and it is given to the vehicle body normal force port. The vehicle body has an H-Hub, S- Tire slip, N- Normal force, A- axel connection, wind velocity, inclination angle. The tires hub is connected as a common node to the vehicle body. The vehicle body wind velocity is connected to a constant block and the beta-inclination angle is connected to another constant block where we can assign wind velocity and inclination angle as per requirement. Velocity is the output port where we can get at which speed the vehicle is moving. The velocity is taken out to the get the distance travelled and state of charge.

Vehicle Body

The Vehicle Body block represents a two-axle vehicle body in longitudinal motion. The vehicle can have the same or a different number of wheels on each axle. For example, two wheels on the front axle and one wheel on the rear axle. The vehicle wheels are assumed identical in size. The vehicle can also have a center of gravity (CG) that is at or below the plane of travel.

Beta- Physical Signal Input Port of Road Inclination Angle.

W- Physical Signal Input of Headwind Speed.

H- Mechanical Translation Conserving Port Associated with the Horizantal Motion of the Vehical Body.

NF- Physical Signal Output of Front normal Wheel Forces.

NR- Physical Signal Output of Rear Normal Wheel Forces.

V- Physical Signal Output Port of Vehicle Velocity.

The block accounts for body mass, aerodynamic drag, road incline, and weight distribution between axles due to acceleration and road profile. Optionally include pitch and suspension dynamics. The vehicle does not move vertically relative to the ground.

The block has an option to include an externally-defined mass and an externally-defined inertia. The mass, inertia, and center of gravity of the vehicle body can vary over the course of simulation in response to system changes.

Wheels

Represents the longitudinal behavior of a highway tire characterized by the tire Magic Formula. The block is built from Tire-Road Interaction (Magic Formula) and Simscape Foundation Library Wheel and Axle blocks. Optionally, the effects of tire inertia, stiffness, and damping can be included.

Connection A is the mechanical rotational conserving port for the wheel axle. Connection H is the mechanical translational conserving port for the wheel hub through which the thrust developed by the tire is applied to the vehicle. Connection N is a physical signal input port that applies the normal force acting on the tire. The force is considered positive if it acts downwards. Connection S is a physical signal output port that reports the tire slip. Optionally expose physical signal port M by setting Parameterize by to Physical signal Magic Formula coefficients. Physical signal port M accepts a four element vector corresponding to the B, C, D, and E Magic Formula coefficients.

Inertia

The block represents an ideal mechanical rotational inertia.

The block has one mechanical rotational conserving port. The block positive direction is from its port to the reference point. This means that the inertia torque is positive if the inertia is accelerated in the positive direction.

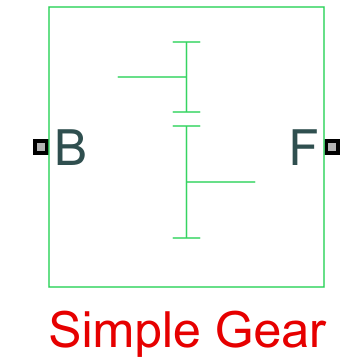

Simple Gear

Represents a fixed-ratio gear or gear box. No inertia or compliance is modeled in this block. You can optionally include gear meshing and viscous bearing losses.

Connections B (base) and F (follower) are mechanical rotational conserving ports. Specify the relation between base and follower rotation directions with the Output shaft rotates parameter. Optionally include thermal effects and expose thermal conserving port H by right-clicking on the block and selecting Simscape block choices to switch between variants.

Output shaft rotates in in same direction of input shaft.

Base is connected to the Motor shaft and the follower is connected to the Rear wheel derive.

Battery And Soc Subsystem Model

Battery

The battery is required to power the controller and motor. The controller uses the battery power according to produce the input given by the motor to obtain maximum speed. The battery is also used to power every electrical component in the vehicle.

The Battery block implements a generic dynamic model that represents the most popular types of rechargeable batteries.

The battery has two-stage one is charging and another one is discharging state.

The battery is of 50 Ah capacity.

The Nominal voltage of the battery is 200V

Initial SoC is 100%

The battery as a series internal resistance plus a charge-dependent voltage source

defined by:

where SoC is the state of charge and Vnom is the nominal voltage.

Coefficient,

beta is calculated to satisfy a user-defined data point [AH1,VI].

The battery has a positive and negative terminal which is given the voltage-controlled source where the battery consumption is controlled by the motor controller and then it is given to the SOC block.

Battery State of Charge

SoC is the percentage or level of battery presents after certain travel or consumption of battery charge by the vehicle.

In the designed vehicle battery charge or SOC is calculated by giving it to the rate transition and then to gain where 1/inominal battery capacity) then to a discrete-time integrator and it will get minus from the 1 as it is considered a 100% of battery and it is multiplied with 100 to get a percentage of battery.

The majority of blocks are simscape blocks were physical to Simulink converter is used to convert the physical signal from simscape block to Simulink signal.

Controlled Current Source

The Controlled Current Source block converts the Simulink input signal into an equivalent current source. The generated current is driven by the input signal of the block. The positive current direction is as shown by the arrow in the block icon.

We can initialize the Controlled Current Source block with a specific AC or DC current. if we want to start the simulation in steady-state the block input must be connected to a signal starting as a sinusoidal or DC waveform corresponding to the initial values

Double click controlled current source and from the drop-down menu of measurement select current.

Signal output will connect with scope by adding the current signal to it. (+) the terminal will connect with the battery (-) terminal.

BUS Selector

The Bus Selector block outputs the signals you select from the input bus The block can output the selected elements separately or in a new virtual bus

Here just we have mange the output and connect it with different Scope Block.

Powergui

- The powerful block allows us to choose one of these methods to solve.

- Continuous, which uses a variable-step solver from Simulink your circuit.

- Discretization of the electrical system for a solution at fixed time steps. Continuous or discrete phasor solution.

- The powerful block also opens tools for steady-state and simulation results analysis and for advanced parameter design.

The distance travelled by the vehicle is calculated

- The model simulated for three drive cycles and the results plotted.

- Assumed parameters in the model is shown below.

All outputs and results displayed and plotted using scope block

RESULT

The vehicle speed performance is shown below

- Graph 1:The speed of the vehicle with respect to the reference speed ,its observed that vehicle tracking the reference speed well.

- Graph 2:The distance travelled by the vehicle for given drive cycle,It oberved the distance is around 0.5km.

The battery performance is shown below.

- Graph 1:The SOC of battery.Its observed that 99% of charge remains in the battery after the executing the drive cycle.

- The regerative braking makes the battery charging ,when the vehicle decceleraitng

- Graph 2:The motor current ,The polarity of current changes according to acceleration and decceleration command.

- Graph 3:The energy consumption,its observed that forthe given drive cycle 2.3Wh energy consumed.

The temperature rise in thesystem is shown below.

- Graph 1:The temperature in converter ,its observed that the temperature steadily increasing upto 273C.

- Graph 2:The temperature in motor,its observed that temperature steadily increasing upto 274C.

CONCLUSION

- Simulink model of an electric rickshaw is designed.

- The model simlated for three different drive cycles and results were plotted.

- The energy consumption ,temperature ofconverter and motor obtained for three driving cycles.

- Its concluded that the model working and tracking all three driving cycles.

Leave a comment

Thanks for choosing to leave a comment. Please keep in mind that all the comments are moderated as per our comment policy, and your email will not be published for privacy reasons. Please leave a personal & meaningful conversation.

Other comments...

Be the first to add a comment

Read more Projects by Pratik Mankar (13)

Week 1 Understanding Different Battery Chemistry

Pratik Mankar AIM To understand different Battery chemistry. OBJECTIVES 1] Prepare a table which includes materials & chemical reactions occurring at the anode and cathode of LCO, LMO, NCA, NMC, LFP and LTO type of lithium ion cells.Give your detailed explanation on it. 2]Compare the differences between…

24 Jan 2023 04:09 AM IST

Final Project: Electric Rickshaw modelling

Pratik Mankar AIM Design of an Electric Rickshaw using MATLAB Simulink (three wheel passenger vehicle). ABSTRACT In this project, we work to create the MATLAB model of the ELECTRIC RICKHAEW by doing a PM brushed type DC motor and a suitable Lithium-Ion battery for the motor. Before this, we will remember…

16 Jan 2023 04:36 PM IST

Project-1: Modelling an electric Car with Li-ion battery

Pratik Mankar AIM To Create a MATLAB model of an electric car in which we uses which uses lithium ion battery and suitable motor choosing a suitable blocks from the Powertrain block set and Implement the Vehicle Speed by using PI Controller and generate the accelerator and brake commands. OBJECTIVES To prepare the…

04 Jan 2023 04:18 AM IST

Project 1 (Mini Project on Vehicle Direction Detection

Pratik Mankar MBD Live Batch 2 Mini Project - Vehicle Direction Determination AIM To create the Vehicle Direction Determination model according to the given requirements. INTRODUCTION Identifying the direction of the vehicle is one of the important & diverse features in Autonomous driving…

30 Sep 2022 11:50 AM IST

Related Courses

Skill-Lync offers industry relevant advanced engineering courses for engineering students by partnering with industry experts.

Our Company

4th Floor, BLOCK-B, Velachery - Tambaram Main Rd, Ram Nagar South, Madipakkam, Chennai, Tamil Nadu 600042.

Top Individual Courses

Top PG Programs

Skill-Lync Plus

Trending Blogs

© 2025 Skill-Lync Inc. All Rights Reserved.